Corvida Medical

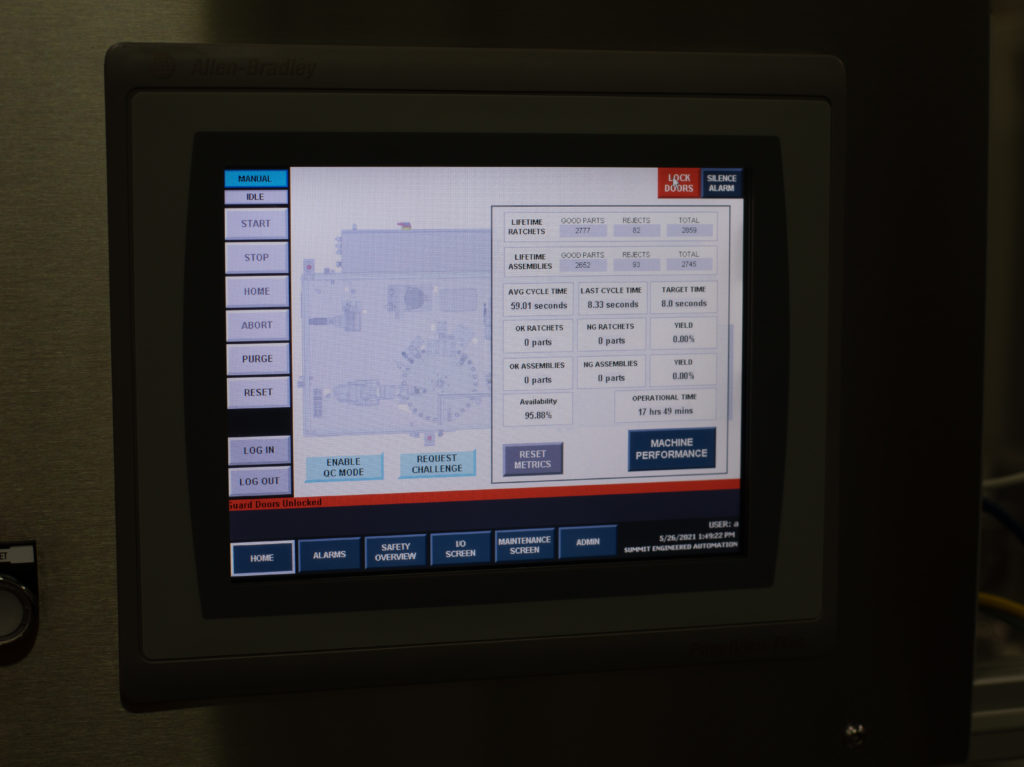

Corvida approached Summit to quote 2 machines, SA Needle Rachet Assembly machine and SA Final Assembly Machine. Summit worked with the customer to create a URS for both pieces of equipment and submitted a proposal for each. Summit was awarded this business and began the engineering phase, before long it became increasingly clear that it made sense to combine the 2 machines into one, this would save on controls cost that could be used for better technology or process, it would also eliminate labor.

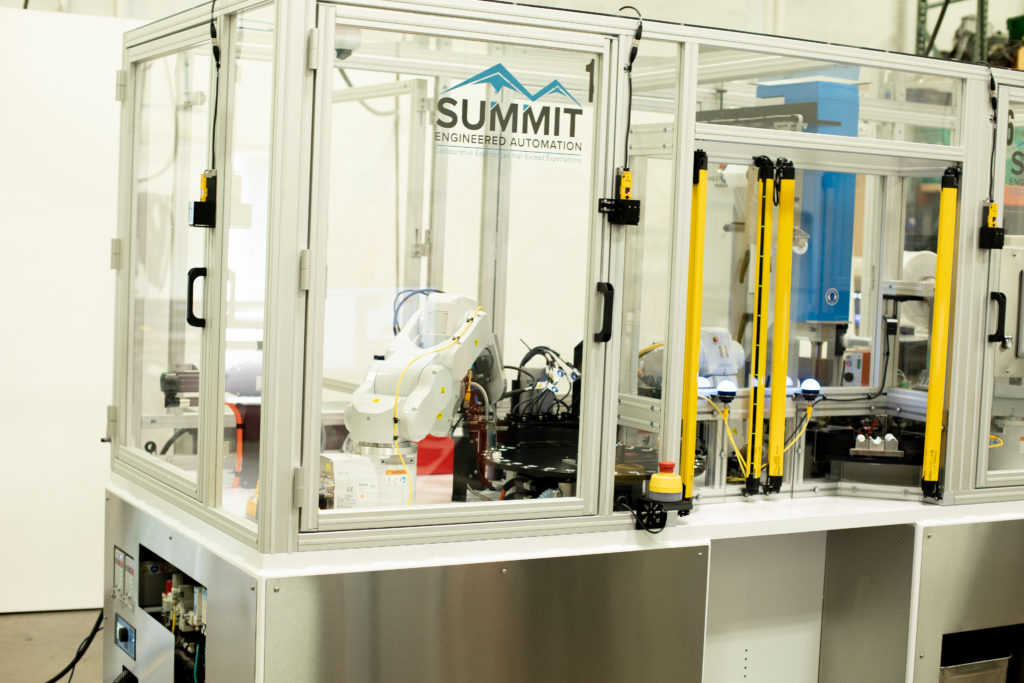

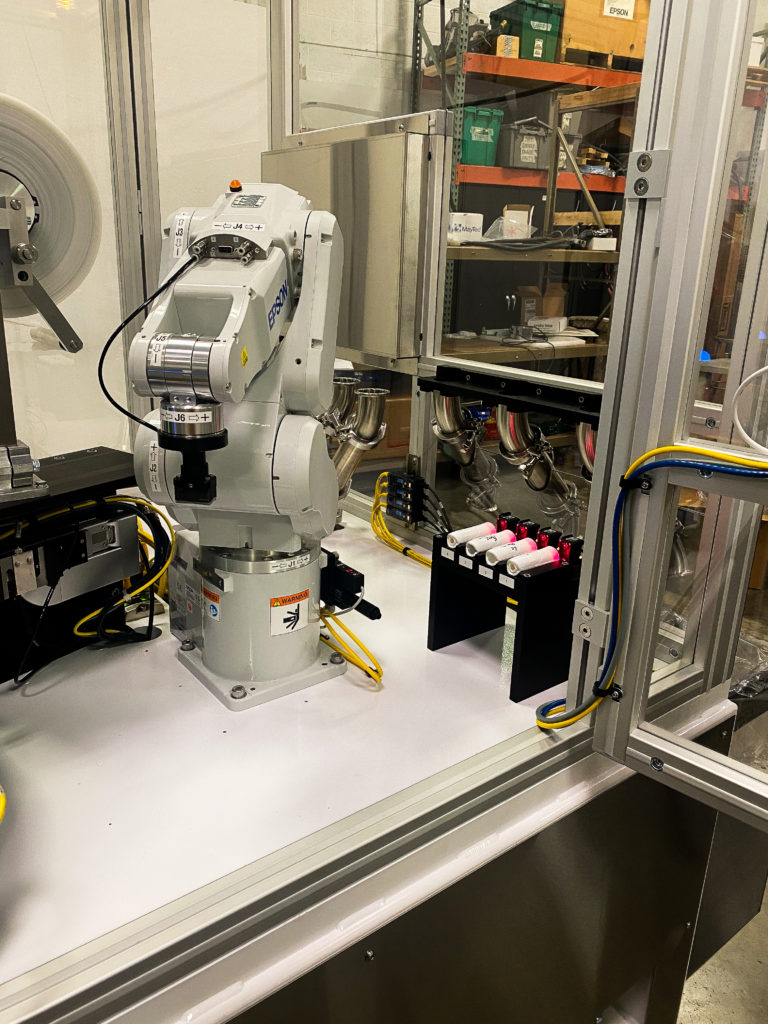

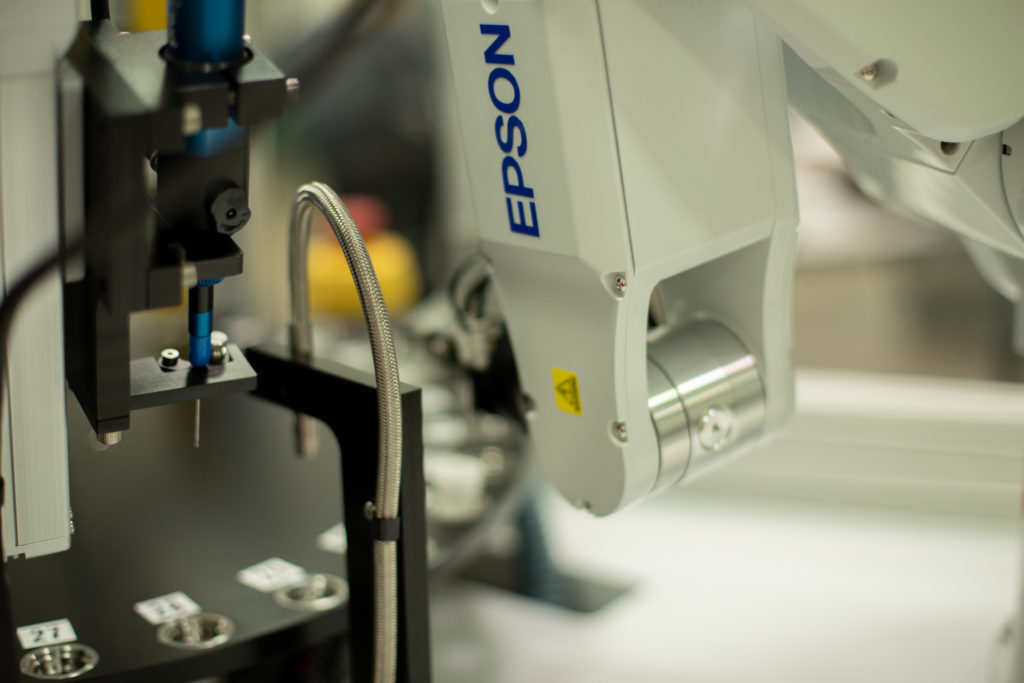

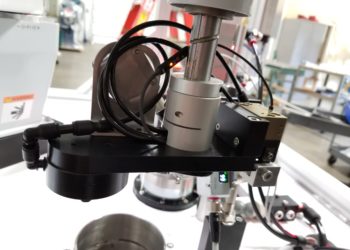

Three EPSON 6-axis robots are integrated with a pair of servo-driven rotary tables to assemble, weld, inspect, and disposition product.

- The operator independently loads both dial tables from the front of the machine

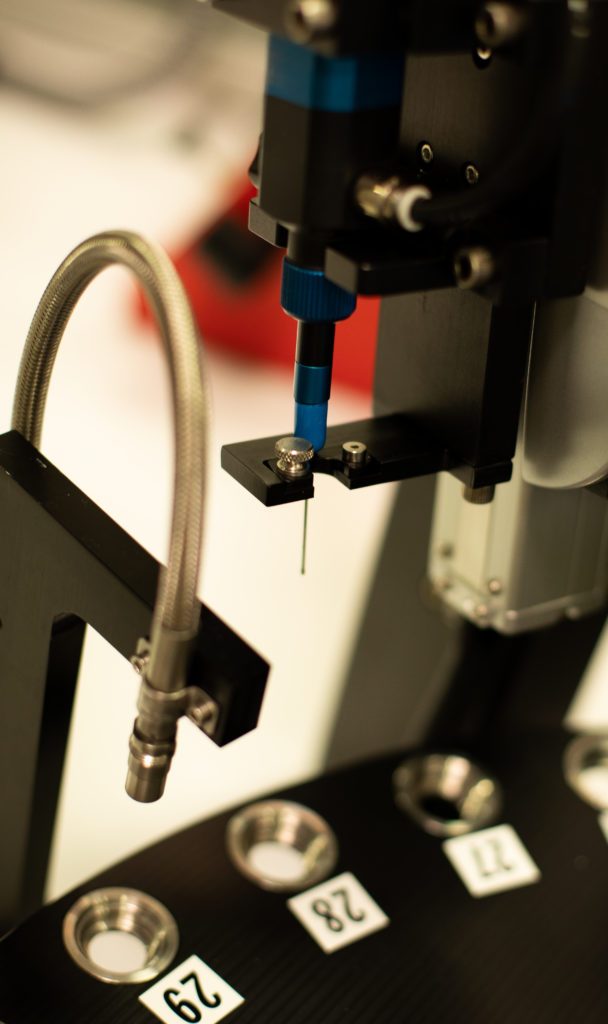

- EPSON C4 robot picks a needle from a drum feeder and inserts it into the ratchet

- Dial table indexes part to be glued and UV cured

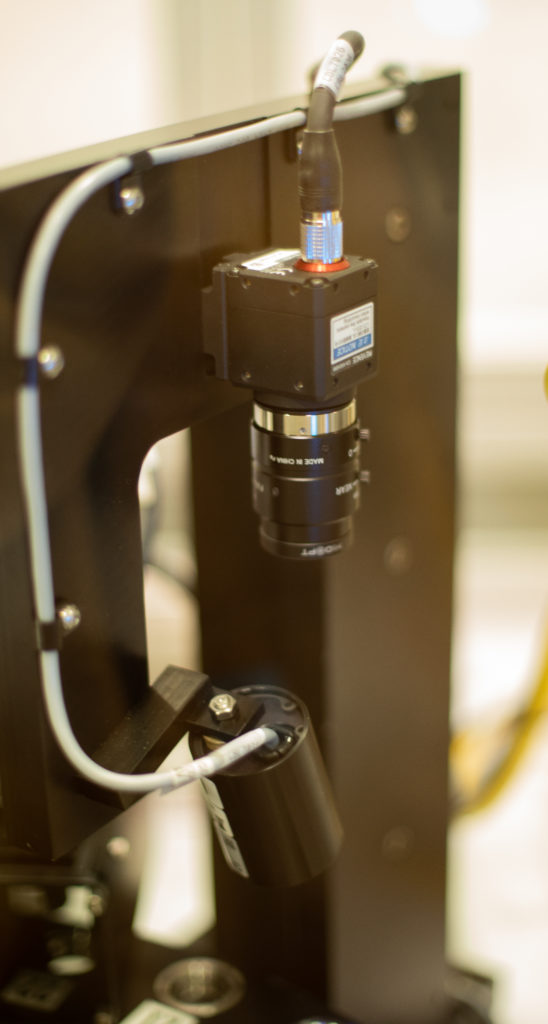

- Keyence CVX vision system inspects glue quality

- The center assembly robot removes the part from the left index table and assembles it into the parts on the right table

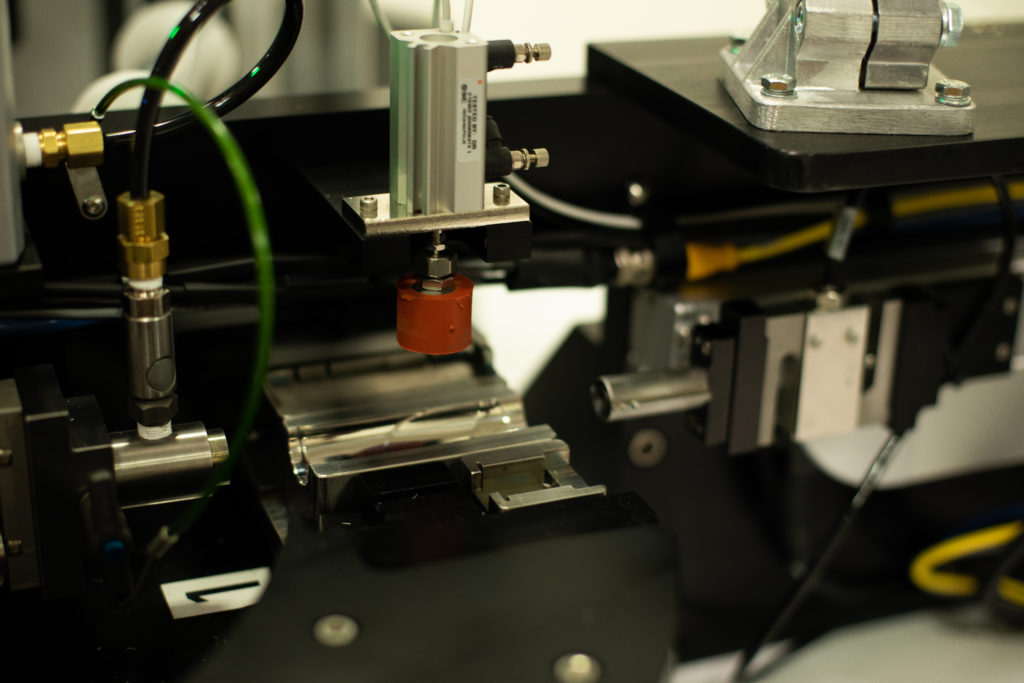

- Assembled part is indexed forward for ultrasonic welding from a Hermann servo welder

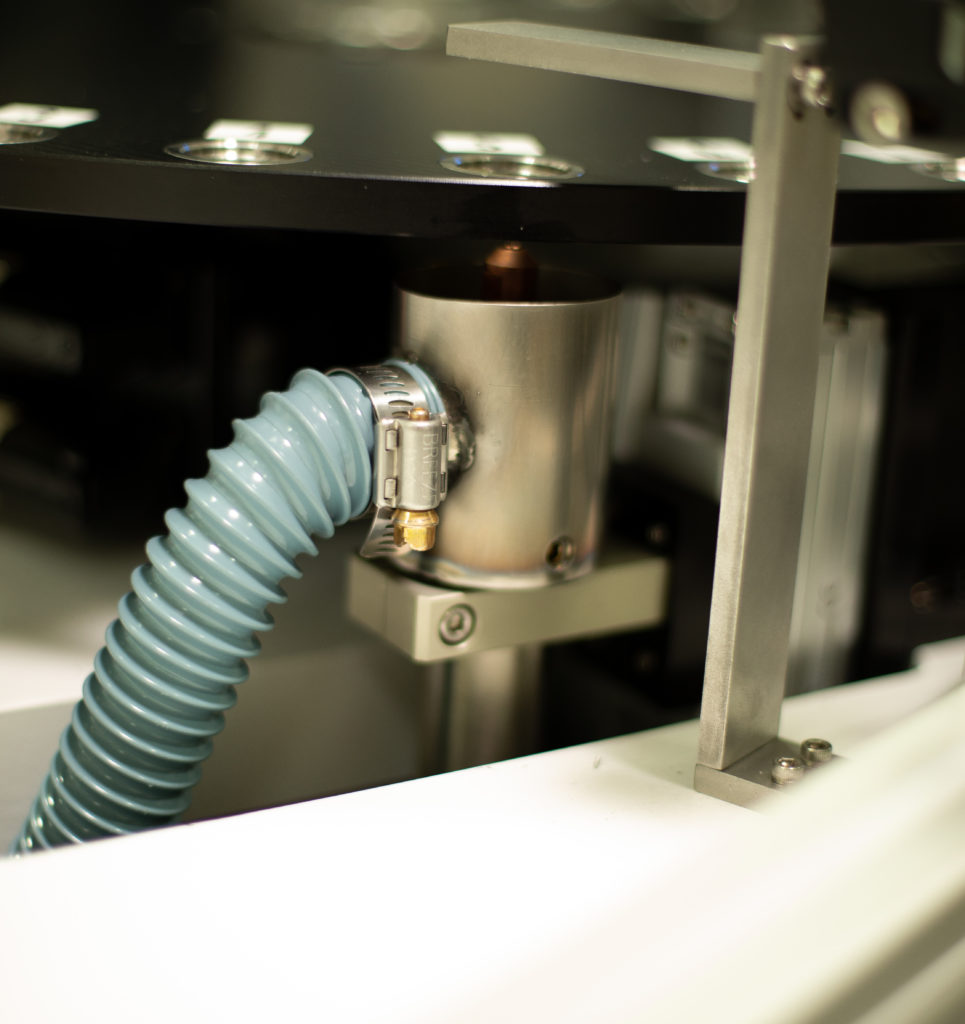

- The part then undergoes leak testing through an Ethernet/IP equipped Z-axis leak tester

- Outfeed robot dispositions the part based on upstream test results

EPSON robots allow the equipment to place a multitude of process steps into a compact and efficient footprint. The flexibility granted through robotic part handling and servo-driven rotary tables allows the machine to run verified OK/NG parts in reverse to verify the results of the test methods.