Custom Machine Automation and

Automation Consulting Services

Summit Engineered Automation designs and builds custom automation solutions, including Plastics Automation Solutions, Medical Automation, Electronics Automation, Manufacturing Automation, and Product Automation. We apply cutting-edge thinking and technologies to save you time and costs while boosting production quality. Learn more about our process or schedule a free consultation.

Custom Machine Automation Solutions

We work with leading companies to provide custom machine automation solutions for manufacturing and production in the medical, pharmaceutical, plastics, electronics, cutting tool, and consumer products industries.

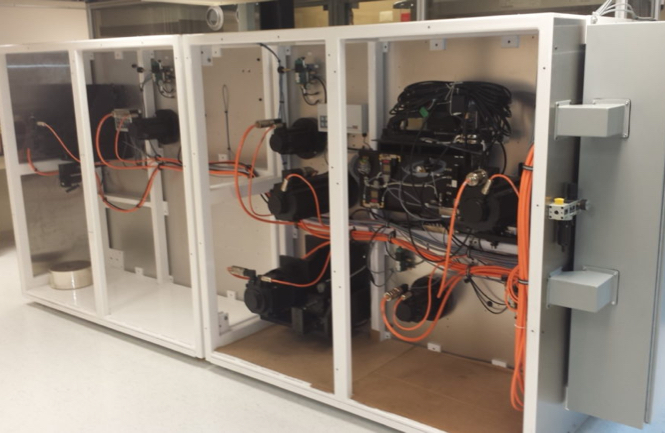

MEdical Automation

We ensure the highest measures of quality and tight tolerances in your medical and pharmaceutical automation projects.

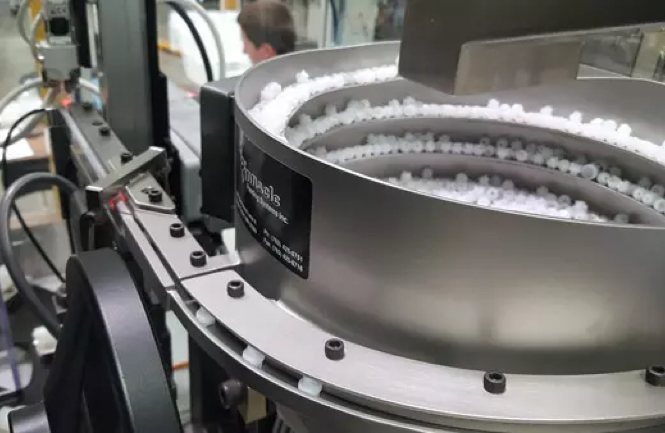

Plastics Automation

We design and build reliable plastics automation solutions and equipment for a broad range of manufacturing applications.

Electronics Automation

We create custom-built electronics automation systems for unique applications in electronics manufacturing.

The Summit Agile Process

In our custom automation services consulting, we use agile methods that emphasize risk analysis and debugging early and throughout the project timeline. Transparent and regular communications foster a close partnership to ensure we exceed your expectations.

Assessing how to reduce variables in your manufacturing process – such as the human element – are creative ways we apply integrated and flexible custom automation consulting to optimize your product’s production. We believe these principles lead to building equipment that will benefit your bottom line.

Budgeting

Project Management

Implementation

Support

Recent Projects

Separator Weld Cell

Automation Consulting Services

Custom machine automation projects require more than just a good idea. There is planning, resourcing, and implementation, all requiring experience and awareness of the impact each step will have on other aspects of your business.

The Summit team provides the knowledge and experience with automation risk management to bring your vision to life. Our automation consulting services are all about working with your team to identify how to implement the best custom machine automation plan for true cost savings and improved productivity.

If you have ever been involved with automation projects that haven’t met your expectations, you know how frustrating it can be. Fortunately, our team is ready to offer a free consultation on how our automation consulting services can drive your business forward into a new age of success.

Contact us to schedule a consultation and learn more. You can also read more about how our custom automation consulting experience and capabilities can match your needs and support your business.