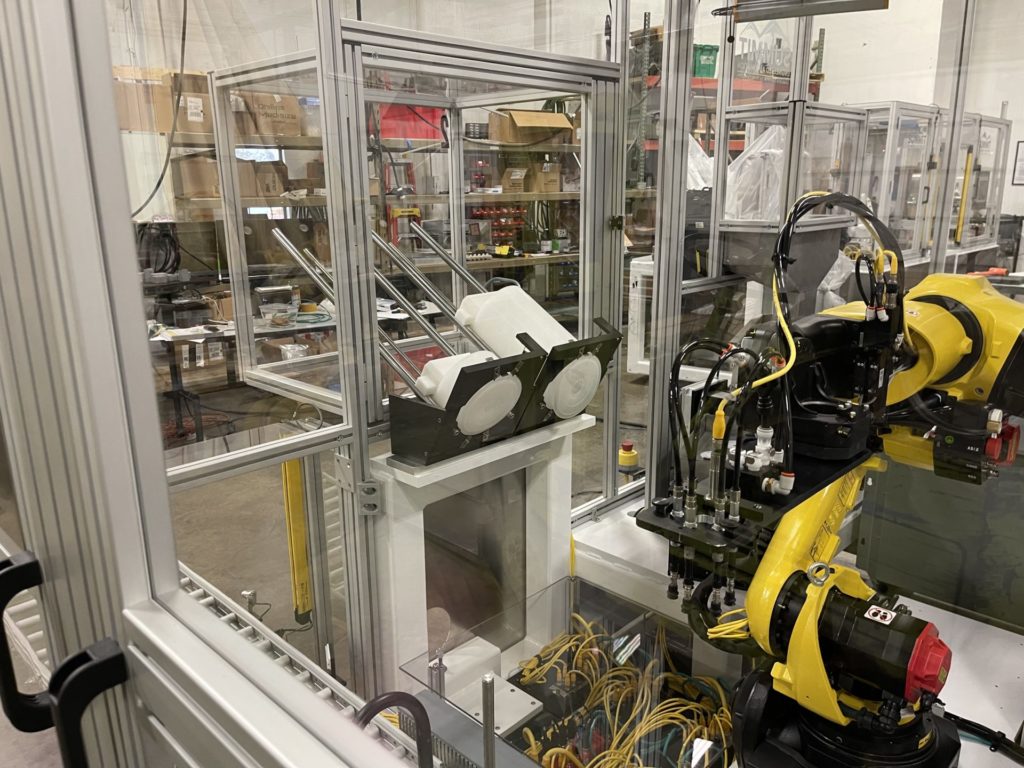

Separator Weld Cell

Summit’s Separator Weld Cell integrates a FANUC M-10iD with an Asycube 530 and Dukane Infinity ultrasonic welder. In this stage of the filter assembly, plastic washers are ultrasonically welded to the separator discs. The process flow is as follows:

- An operator selects the appropriate recipe on the HMI to establish process parameters

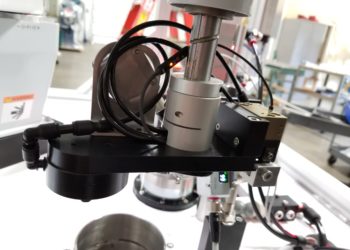

- Plastic washers are fed from an Asycube530 smart feeder and located with Asyril’s eye+ integrated vision system

- A FANUC M-10iD 6-axis robot places the washers on a weld fixture

- FANUC robot picks a separator and identifies its rotational position using a Keyence camera

- Separator is placed on top of the washer

- Dukane Infinity ultrasonic welder welds the parts

- Parts are dispositioned based on reported weld quality

The use of smart feeding technology, vision-assisted robotic picking, and a servo-electric ultrasonic welder provides this piece of equipment with the flexibility to run any configuration of parts. Toolless changeover and single-button recipe selection means that the machine can be configured any time at a moment’s notice.