Automation Services

Automation Solutions & Robotic Machines That Streamline Production & Grow Your Bottom Line

Engineered automation to optimize your manufacturing.

To remain competitive, today’s manufacturers leverage automation services and robotic machines to increase factory productivity and decrease costs, which drives up your profits.

Our specialty is delivering engineered automation, or ways to remove variation, especially the human element.

You’ll find that custom-designed, flexible automation solutions can maximize quality, eliminate variables impacting reliability, and significantly improve your speed to market. Our more than 20 years of cross-industry experience and knowledge help fuel our creative approach and project performance objectives.

A Preferred AUTOMATION MACHINE Supplier to Manufacturing Companies in Multiple Industries

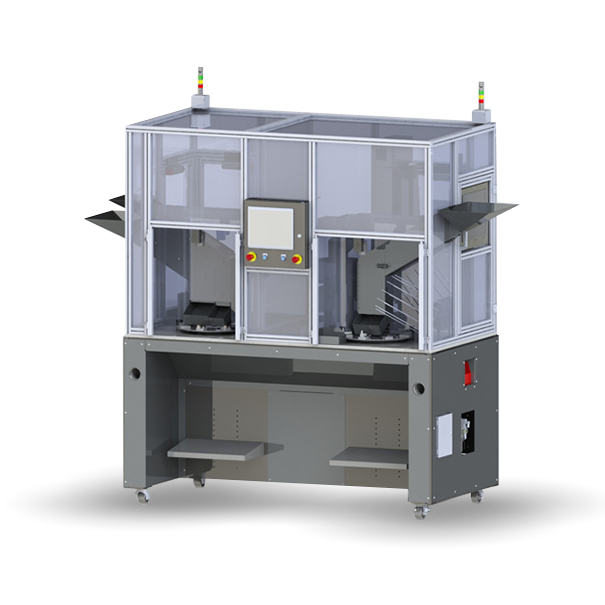

Summit Engineered Automation is a preferred supplier to numerous manufacturing companies. We’ve completed projects in a variety of industries — medical, plastics, electronics, manufacturing and consumer products — with a focus on medical technology.

Explore these innovative projects ranging from a robotic medical assembly device to a vision inspection system and a bag-in-a-box valve assembly machine.

The Summit Agile Process

Agile Project Management Processes Ensure Your Machine Meets Your Needs

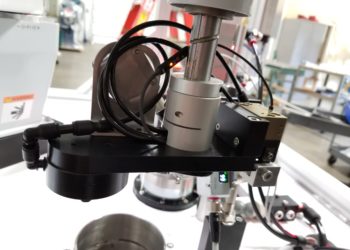

Using our agile project management process, we use a range of products and capabilities to design and build machines that precisely meet your needs. Summit has diverse experience integrating robots, PLCs, sensors, testing and visions systems, conveyors, adhesives and other technologies for the ideal automated machine.

Budgeting

Project Management

Implementation

Support

Over time, we’ve built our agile project management processes on four cornerstones:

- Emphasize risk analysis early and throughout

- Enhance communications between all parties

- Ensure the machine exceeds your expectations

- Develop long-term partnerships on multiple projects

The secret to employing agile practices is a close partnership with your team. Early collaboration, transparent communications, proof of concepts, and iterative early design ensure we deliver a final product that meets all of your requirements.

We employ ingenuity and intelligent design that emphasizes early risk analysis for specific applications before we complete them. We also test your equipment and components to verify each is working to your performance specs and requirements before delivery, reducing risk and lost time due to maintenance downtime. During implementation and your factory acceptance test (FAT), we work together to safely transport and install your new equipment.

In addition to guiding every project we design and build for you, our agile processes makes it easy for you to access time and material costs plus ROI estimates through your customized portal.

A Network of Class-Leading AUTOMATION Component Suppliers

To design and build class-leading automation machines, our engineers work with an extensive network of suppliers that provide robots, sensors and vision systems, pneumatic components, PLCs, adhesive dispensers, conveyors and gear-drive systems. These companies include industry leaders such as:

ATS Automation with SuperTrack, Wittenstein, Galaxie, and many more

Explore Summit’s Capabilities

- Flexible and fixed automation

- Work cells

- Integrated solutions

- Plastics assembly

- Multiple parts handling and assembly

- Leak detection and testing

- Vision inspection systems

- Conveying solutions

- Converting

- Web handling (coating, printing, slitting, sheeting, wind/rewind)

- Robot integration, using leading vendors

- Material handling

- Sonic welding

- Adhesive dispense UV cure

- Panel scoring

Read our blog posts for examples of our capabilities and the technology tools used.