CAD Manufacturing

Modern design technology gives you full visibility and control when engineering your automated solution.

Computer-Aided Design and Manufacturing

Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) are the future of design engineering. Static schematics have always been valuable when designing and manufacturing solutions, but when it comes to custom machinery, they don’t hold up in the face of rapidly evolving iterations.

When you’re in the middle of the design process, you need access to real-time edits and digital prototypes that come together as quickly as your ideas. You’re creating a custom automation solution to bring your company into the future, and your design and manufacturing processes should be just as forward-thinking.

How is CAD Used in Manufacturing?

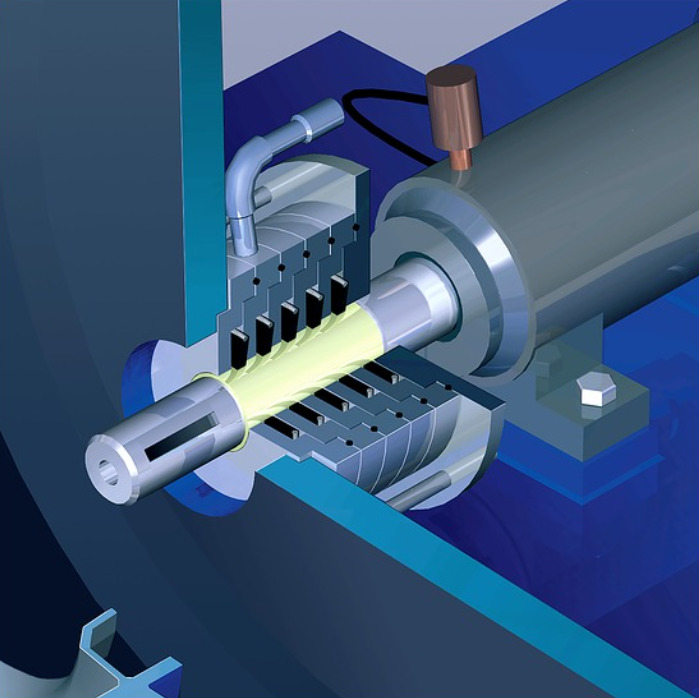

CAD/CAM software uses generative design principles and 3D modeling to create computer models of machinery. These programs primarily create interactive pre-production models, but they can also be programmed to control automated machinery once it’s installed.

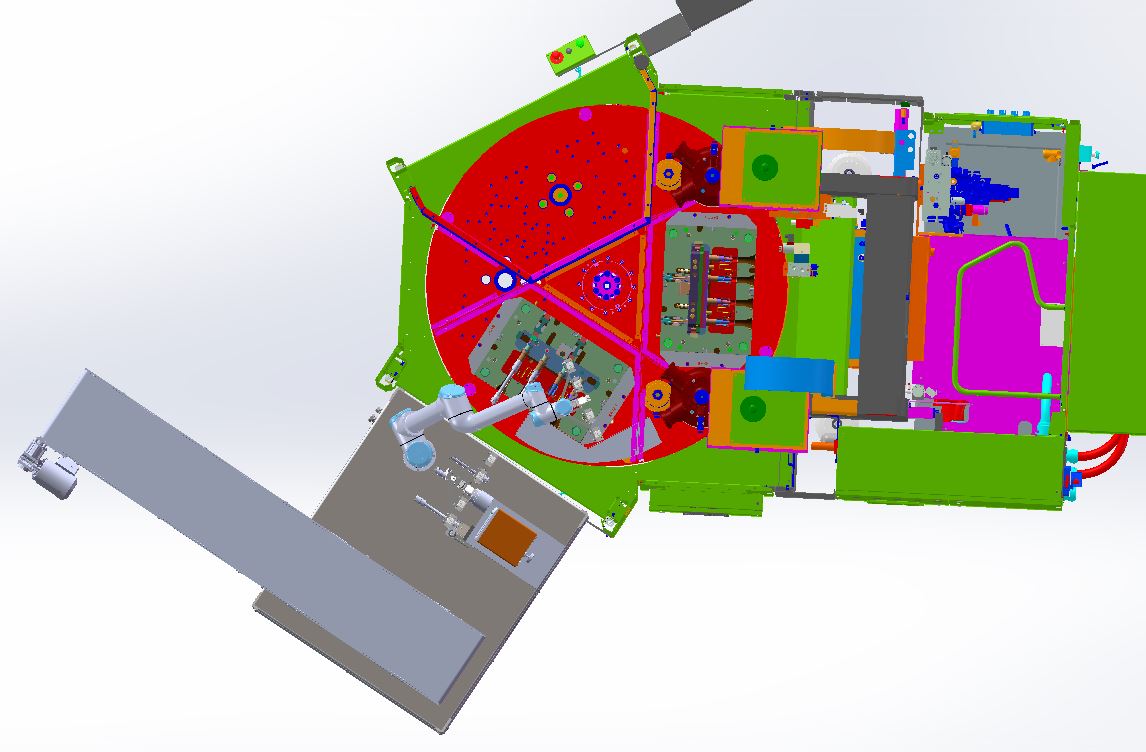

CAD manufacturing models accelerate both the design and manufacturing processes by providing interactive, flexible, data-driven digital prototypes. These models can serve as mockups of entire systems or focus on a single machine part in need of improvement. Both CAD and CAM use numerical control to encode geometrical data that accurately models form and function. In other words, if you can think it, you can code it—and then create it.

Benefits of CAD Manufacturing

Computer-Aided Design streamlines the digital prototyping process, allowing designers to tinker with and improve models without the risk of losing time or money. Producing and installing new machinery solutions gets expensive. CAD software helps keep your team within budget during the design period and then provides installation support through digital imagery.

3D CAD technology allows you to get a sense for the feel and look of your solution even before you give the green light on production. For organizations looking to not only solve design challenges but to integrate new solutions into existing machinery, this type of hands-on insight is critical.

CAD files also preserve your designs for future alterations. When all of your designs and prototypes are stored safely in the Cloud, you maintain ownership and consistency for new employees and new design partners.

CAD Manufacturing and the Summit Agile Process

The Summit Engineered Agile Process focuses on full visibility and transparency during production to ensure quality work and seamless collaboration. Our shared design portal is a unique and essential part of our work. We never want to limit our client’s ideas or involvement.

With our design portal, you get unlimited access to your prototype designs and automated schematics. Combined with the flexibility of our CAD manufacturing automation system, there are no limits to when or where you can make adjustments to your custom solutions.

Contact Summit to start designing your next project today with CAD automation.