Robotics Systems for industrial automation

Custom robotic processes streamline and enhance manufacturing operations by flexibly integrating with your current systems.

Robotic automation in automation solutions

Robotics and robotic solutions are a pillar of modern manufacturing. These technologies support the continuous evolution of your manufacturing processes and are at the forefront of a new industrial revolution—allowing for increasingly complex capabilities and radical efficiency in your production line. Ranging in size from microscopic to warehouse-sized, robots offer flexible, affordable solutions to any type of product manufacturing.

Whether you’re building a brand-new system or updating legacy machinery, robotics have the power to transform your productivity, safety, and budget.

How are robotics used in automation systems?

While basic robotics and robots for heavy lifting have been an industrial standard for years, Robotic Process Automation (RPA) has redefined robotic potential in manufacturing over the last decade. These new advances continue to push the boundaries of API integration and AI applications, creating more task-specific robots and robot controllers.

A few key industries benefiting from robotics in automation systems include:

- Agriculture and farming

- Food processing

- Healthcare and pharmaceuticals

- Plastic and metal manufacturing

- Welding and fabrication

- Painting and sprays

Medical and food & beverage packaging plants in particular can derive enormous benefits from utilizing robotic systems that guarantee better sanitation and product preservation. As shipping methods shift and health and safety standards increase, robots provide an advantage when production facilities require strict product and packaging quality.

The benefits of industry robotics

Robotic processes can enhance every aspect of a manufacturing business, increasing profits and decreasing injury and waste.

A few of the most transformative benefits of robotic automation systems include:

1. Increased accuracy: Robots can work with unparalleled precision, particularly when it comes to small electronic parts or medical vials. Robots’ programmed, consistent motion, better-than-human eyesight and accuracy, and microscopic application size means they are already indispensable in certain industries.

2. Increased efficiency: Robotic solutions can be programmed to work at a set pace with around-the-clock hours. Combined with the benefits of increased accuracy, this efficiency allows robots to turn out significantly more product in noticeably less time without endangering quality.

3. Increased worker safety: When robotic arms take over for human ones, they save workers from repetitive motion injuries as well as potential exposure to harmful temperatures or chemicals. This increases worker longevity and allows humans to dedicate their creative eye to more productive tasks.

4. Opportunity expansion: Not only do robotics solutions allow for new internal opportunities, they also promote business development by increasing the number of products a plant is able to handle. When companies create more products for less money, they have the chance to expand their audience base.

5. Decreased product waste: One of the largest financial hits manufacturers suffer every year comes from damaged or destroyed products on the line. With accuracy and testing, robotic systems significantly decrease that waste, leading to more sellable goods and fewer wasted hours and dollars.

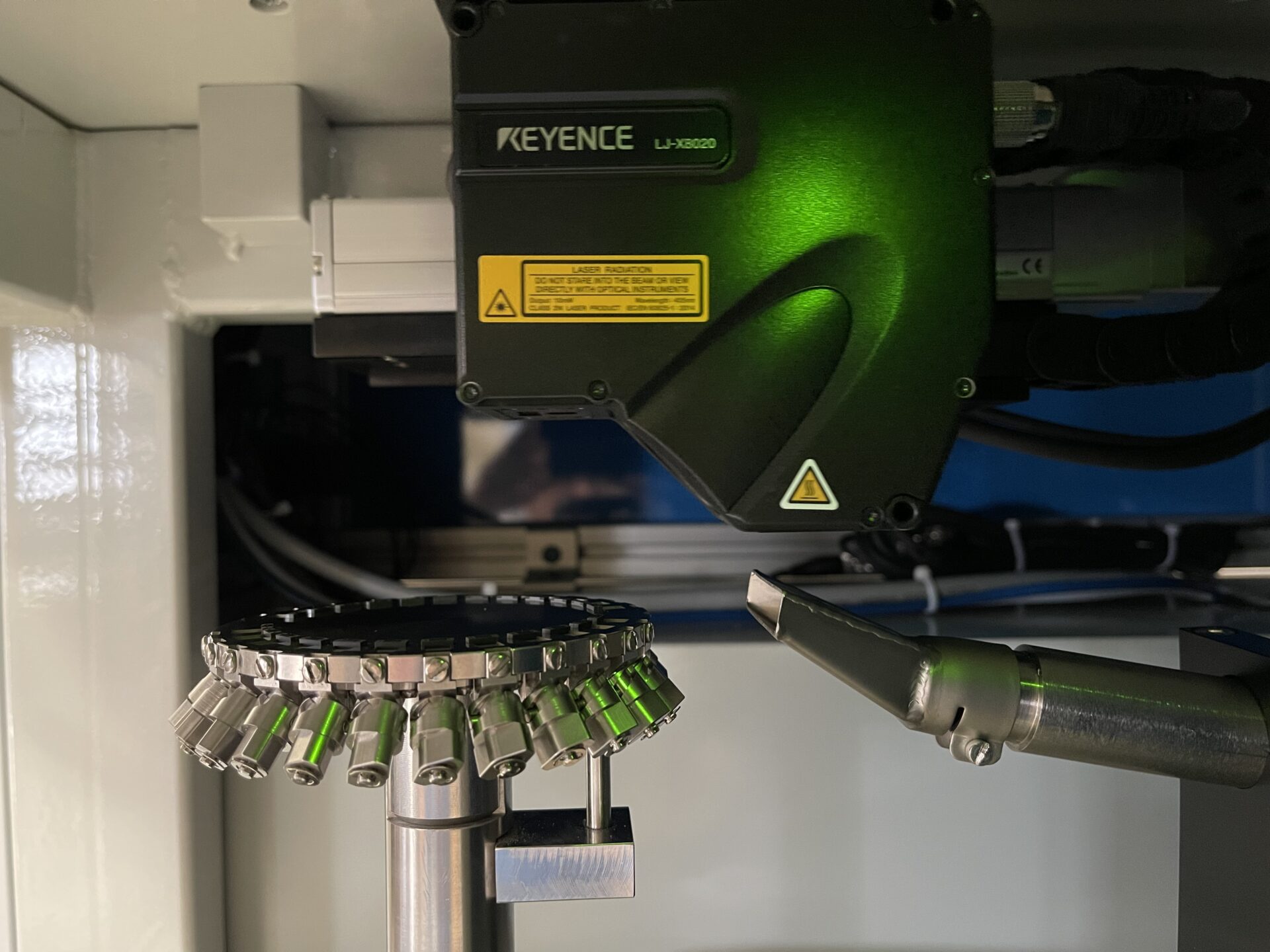

Summit robotics custom automation

Summit Engineered Automation works directly with your team to provide brand-new robotic solutions. Our numerous partnerships give us access to the best possible cutting-edge robotics, meaning your company never has to settle for anything less than the ideal system.

Using our unique design portal, Summit works with you to create a custom system designed for your particular robotic automation needs. We focus on full transparency with an emphasis on user experience, affordability, and creative integrity.

Contact Summit Engineered Automation today to discover what custom robotic automation can do for your production line.