advanced medical automation solutions

With 25 years of experience designing and building medical automation equipment and systems for discerning engineers, Summit has emerged as a trusted collaborator and custom builder for medical and pharmaceutical companies looking for inventive solutions to classic production problems.

Pharmaceutical and medical Automation Equipment

bring cutting edge technology to your manufacturing process

Manufacturing products for medical applications and pharmaceutical automation demand the highest measures of quality and tight tolerances, as well as improved production output. The equipment and systems that make mass production of medical products and pharma automation possible are some of the most complex and challenging to build in the industry.

We understand your concern with consistent product quality, lower manufacturing costs, higher productivity, and faster speed to market, Summit Engineered Automation equipment is designed and customized with your needs in mind. Our team of experienced medical automation equipment designers has been able to help numerous manufacturers develop the perfect systems for their production needs.

Whether you’re seeking solutions for medical device assembly automation or need pharmaceutical process control, we have the engineering expertise and tools to have you up and running fast and efficiently. We refuse to cut corners while still maintaining an eye on the most effective and efficient way to help you achieve your goals.

With deep industry experience in designing medical automation systems, we can help you anticipate medical regulatory requirements. For instance, the FDA requires part-by-part documentation of machine parameters, including deviations. Custom machine automation solutions with back-end support can collect and store individual part data during manufacturing, which makes verification easier and simpler for you.

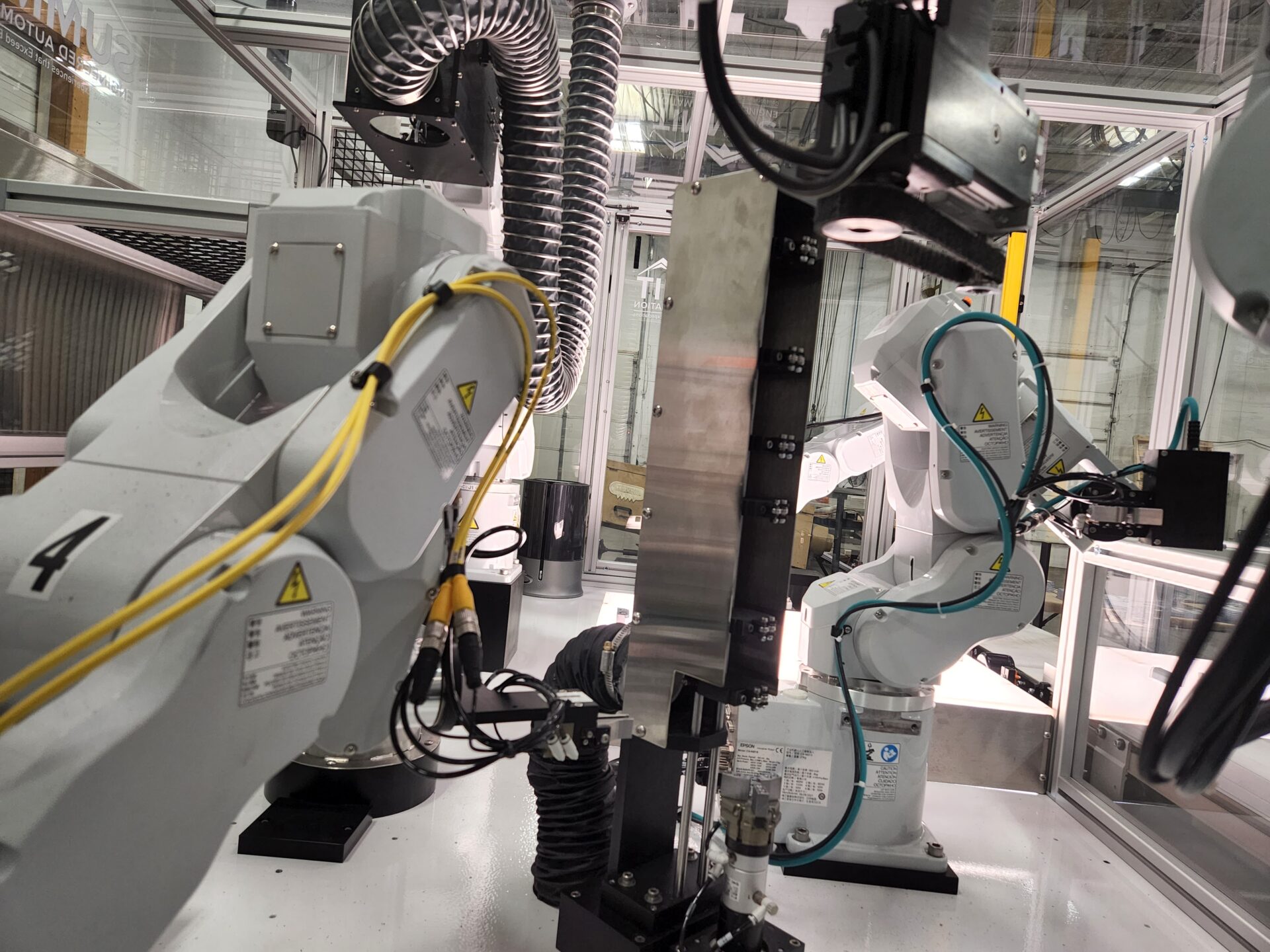

As your customers’ demands continue to rise, you need a reliable supplier that knows the unique challenges of the medical automation systems industry. From robotic equipment to vision systems and conveyors and control systems, we’ll design and deliver medical automation equipment that surpasses your expectations.

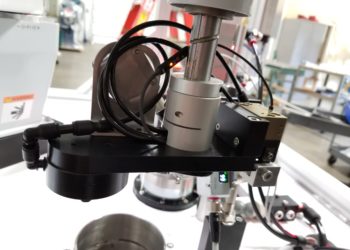

In one innovative example, we designed a machine that tested pacemaker leads using abrasion. Our client tested the leads until they failed and analyzed the data to help them design more robust leads.

MEDICAL AUTOMATION EQUIPMENT THAT uses RoboticS, control systems, vision systems, and conveyors to deliver results.

Robotic equipment, vision systems, conveyors, and control systems are all part of the medical automation equipment designs we can create to help you improve your automated manufacturing systems. Summit Engineered Automation goes beyond the basics, however, with innovative engineering and an agile project management process that results in higher productivity for the machines in our customer’s facilities. Those increases in OEE (overall equipment effectiveness) metrics allow for higher revenue and more consistent results. This is why partnering with Summit for our medical automation services and systems is so valuable. Together we can positively impact your supply chain in the following ways:

✓ Higher quality products

✓ Lower manufacturing costs

✓ Faster speed to market

✓ Lower labor costs

✓ Higher productivity

Experience & Engineering Expertise in Medical Manufacturing

The process of creating a new medical device or production line takes years of research, testing, prototypes and further development. Summit Engineered Automation is here to help you take your product from the design stage into the hands of the end user. Our process and engineering expertise provides you with a trusted partner to help you see your product launch and production get started. We strive to bring you the best team and automated system to meet all of your industry needs:

- 25+ years of experience in the medical device assembly and pharma automation market.

- Engineering expertise in mechanical, electrical, automation and controls that help deliver state of the art equipment and technology.

- Tools and production facilities to have you up and running fast and efficiently.

- Development of automated equipment and systems that bring you immediate ROI. We refuse to cut corners while still maintaining an eye on the most effective and efficient way to help you achieve your goals.

- We understand medical regulatory requirements and FDA documentation of machine parameters and deviations. We provide solutions with back-end support that can collect and store individual part data during manufacturing, which makes verification easier and simpler for you.

- We are a reliable supplier for the medical automation equipment and systems and with a full engineering staff and production facility, we control timelines and deliverables without relying on outside vendors or partners.

We will design and deliver medical automation equipment that surpasses your expectations.

Our Process

Summit Engineered Automation understands that the launch and development of a product line is critical to your business success. Our risk management and Summit Agile Process helps provide a strong foundation and communication structure that ensures both teams understand proof of concepts, next steps in collaboration and consulting, final models and build out of final product and implementation.

We are building a long term relationship with you focused on communication, collaboration and automation.

We strive to be up front and communicate on all aspects of the project and we are available from the first phone call throughout the lifetime of the automation equipment.

Learn more about our Summit Agile Process.

Highlighted Medical Device & Pharma Automation Projects:

- Innovated Machine Designed to Test Pacemaker Leads: We designed a machine that tested pacemaker leads using abrasion. Our client tested the leads until they failed and analyzed the data to help them design more robust leads. Project photos.

- Engineering & Understanding Processes Helps Streamline the Job of 2 Machines Into 1: Partnering with Corvida Medical, Summit Engineered Automation took the time to understand Corvida’s project goals, process and overall end results to develop 1 piece of automated equipment versus 2 with the use of robots. This 1 machine saved on control costs, overall labor and had a better plan for technology and process. Read More.

Related Medical Automation Projects

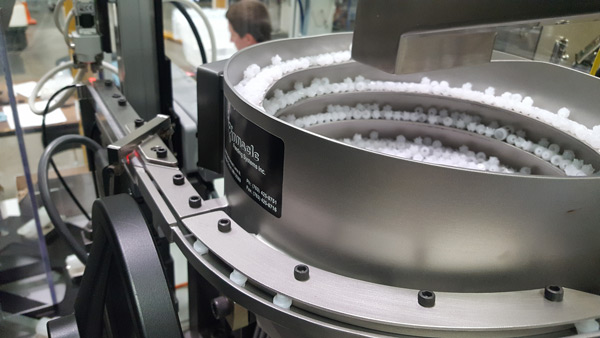

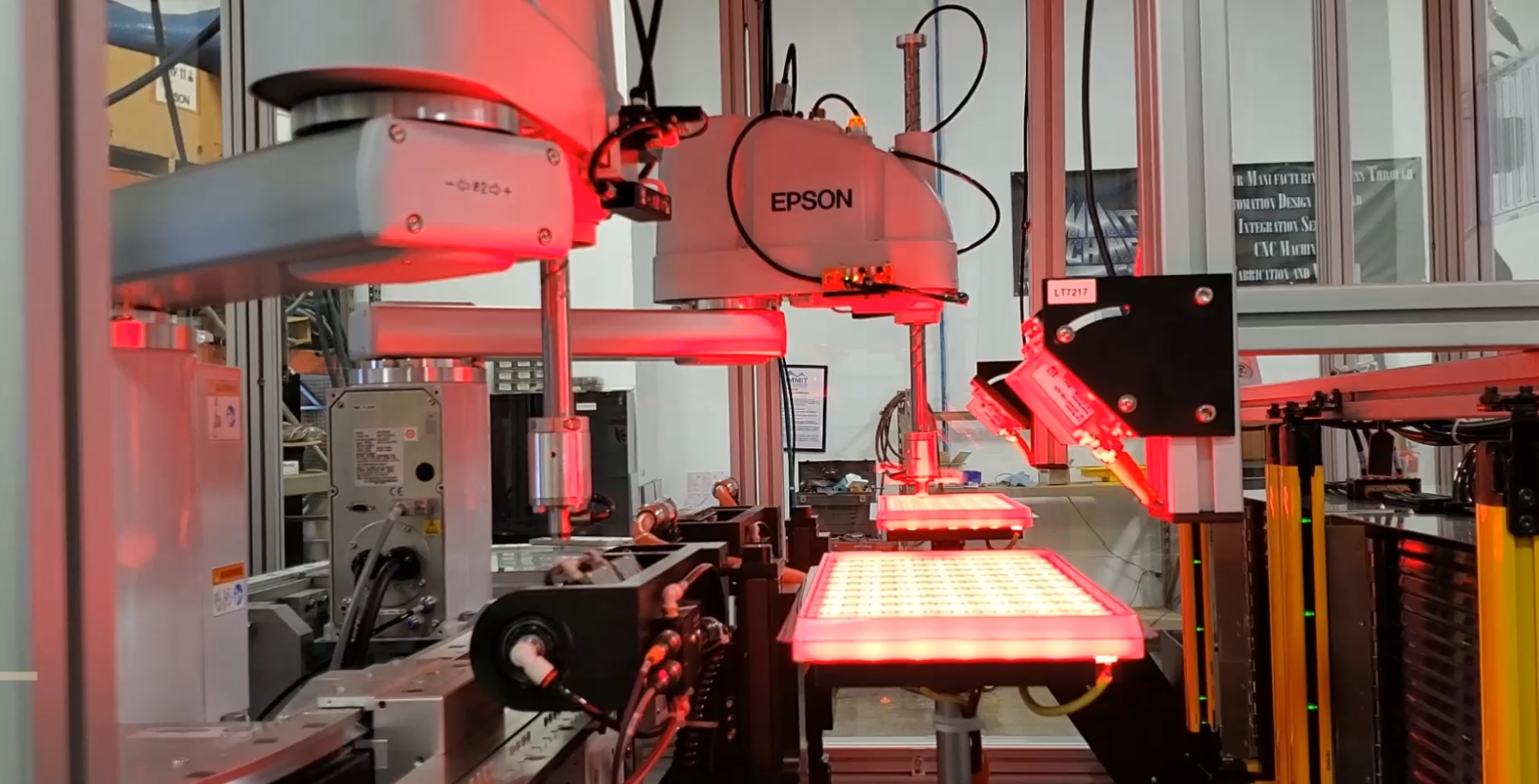

DIABETES SENSOR NEEDLE AUTOLOAD SYSTEM INCREASES PRODUCTION BY 120%

Summit designed and built an automated line around a B&R Industrial Automation SuperTrak® transport system with several Epson Robots with Millibar EOAT. Prior to the autoload system the company was using four workers to manually place insulin sensor needles into an injection molding press. The new medical automation systems helped our client increase production by 120% while cutting labor costs by half.

We are Looking Forward to Working with You:

Summit Engineered Automation is looking forward to working with you on your next project. Our technology, engineering and customer service are second to none. We are your partner from the first phone call through the lifetime of your equipment and automated systems. Your success is a reflection of our work and partnership.

Tell us about your project.