Plastics Injection molding automation

For 25 years, we’ve been designing and building plastics automation solutions and equipment for a broad range of applications.

PLASTIC INJECTION MOLDING AUTOMATION THAT will GROW YOUR COMPANY

Plastics automation equipment runs the gamut from injection molding automation to plastic packing automation. For 25 years, we’ve been designing and building plastics automation solutions and equipment for a broad range of applications.

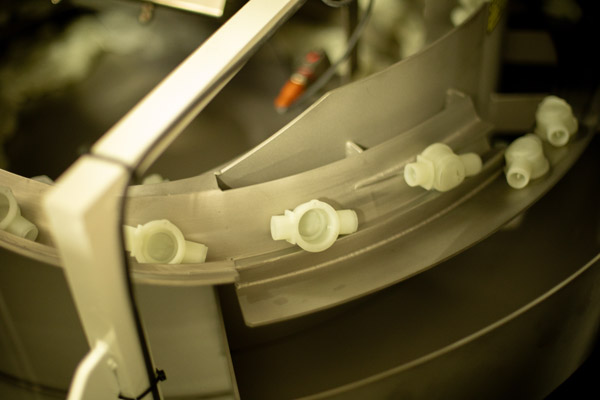

Companies turn to Summit Engineered Automation for inventive solutions to tough plastics industry automation challenges. Take, for example, a bag in a box valve assembly machine. This custom system uses Epson robots and precision cameras from Verkada.

A BAG-IN-A-BOX ASSEMBLY MACHINE IMPROVES QUALITY, SPEEDS PRODUCTION

The machine auto feeds stems and bodies. Robots pick and place the stem and assemble the body to the stem. Vision systems inspect the bags for short shots, and leak tests each assembly. With every pallet full (30 boxes), the machine runs through a challenge routine to ensure vision and leak tests are correctly calibrated.

Check out our Plastics Automation Case Studies.

Related Projects

NEW THERMOPLASTICS, BACTERIA-RESISTANT MATERIALS, OPEN NEW MARKETS

Whether you’re seeking solutions for injection molding automation or need to improve packaging throughput and quality, we have the custom machine automation engineering expertise and tools to have you up and running fast. With plastic injection molding automation demand growing due to emerging plastic varieties, we are designing and delivering custom new equipment for our clients.

New thermoplastics offer improved flexibility, heat resistance, opacity levels, durability, and conductivity. Additionally, the materials are available in highly customizable colors and appearances. What’s more, amid the pandemic, manufacturers are creating more products with new bacteria-resistant plastics and materials that are easier to clean, sanitize, and maintain. We’ll help you tap into these growing markets by building new plastics automation equipment or retrofitting existing machines.

PLASTICS AUTOMATION SYSTEMS DESIGNED WITH THE BEST IN Robotic equipment, control systems, conveyors, AND vision systems.

Summit Engineered Automation has worked hard to stand apart from other plastics automation solutions companies. When your plastics manufacturing facility needs a creative and innovative approach, we work with you to design custom plastics automation solutions. We use the same toolbox of conveyors and control systems, robotic equipment, and vision systems, but we do it in a way that is truly custom to fit your needs no matter the challenge. This leads to better OEE (overall equipment effectiveness) that is measurable and consistent. That means more dependable results which produce higher revenue and quality. Summit has a customized plastics automation approach that culminates in three essential benefits for your supply chain:

✓ Higher quality products

✓ Lower manufacturing costs

✓ Faster speed to market

GET READY FOR INTERNET 5.0, AI, and MACHINE LEARNING

Along with Industry 4.0, Internet 5.0 is providing more automated control capabilities to plastics than ever. For example, temperature control and injection pressure are more easily monitored, which gives you more control while improving productivity and quality. Through Industry 4.0 and IIoT initiatives, AI and machine learning technologies are fueling the rise of the smart factory.

Artificial intelligence and machine learning applications in manufacturing help leaders improve yield rates by detecting defects. Additionally, many manufacturers are able to reduce test and calibration time by 35% using machine learning technology. Whether you need plastics automation, medical automation equipment, or other manufacturing automation services, Summit is here to help.

FAST RESPONSE TIME FOR ANY SERVICE NEED

Summit has a record of successfully developing manufacturing systems for the plastics automation industry that are effective and durable, very often running flawlessly for many years without disruption. When the occasion arises that you do need service you need not worry. Our industry-leading response time is approximately four hours following your call, ensuring limited downtime and higher productivity. Now that’s true customer service!

Tell us about your project.