Product automation solutions

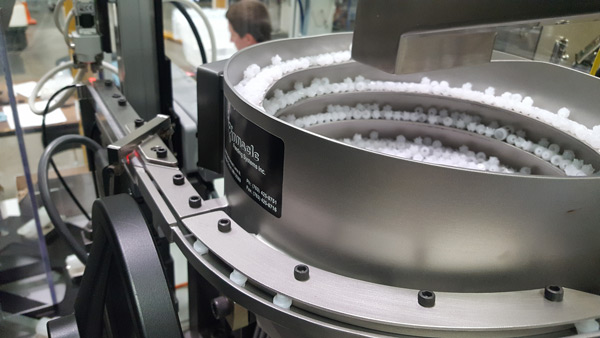

For 25 years, Summit Engineered Automation has been designing and delivering custom machines and systems that help companies improve quality while simultaneously increasing throughput for consumer automation. Industry 4.0 technologies continue to drive the evolution of sophisticated robots, vision systems, conveyors, and control systems.

Product Automation Equipment for consumer automation That Improves Quality, Increases Output

Consumer product manufacturers often need a broad range of custom automation systems. These include everything from product design automation to product test automation systems. Summit Engineered Automation provides industry-leading automation consulting services to help enhance your product automation and deliver the best solutions.

We partner with you to design and build product automation equipment that’ll:

- Lower labor costs – A single machine can often perform the work of three to five people.

- Help you manage in a tight labor market – Worker demand is at an all-time high with widespread shortages and more people choosing to leave their jobs.

- Increase productivity – Machines can run 24 x 7 at maximum performance without human intervention.

- Deliver better product quality – Machines are typically more accurate, produce fewer errors, and deliver more consistent results than people.

- Increase workplace safety – Because of automation, hazardous manufacturing tasks — such as injecting hazardous chemicals or liquids into containers — don’t have to be done by your employees.

Related Projects

PRODUCT AUTOMATION EQUIPMENT AT WORK

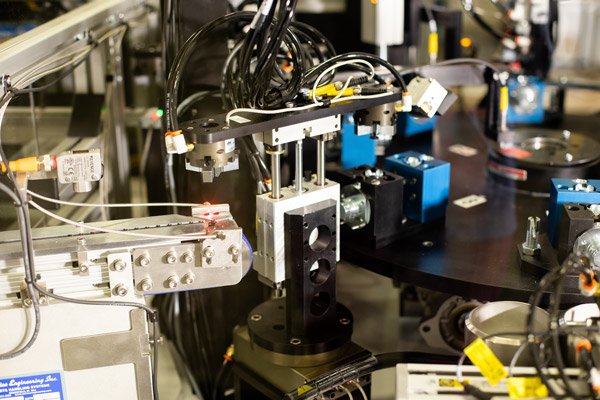

A water filter assembly machine that does it all

Take, for example, a water filter assembly machine that uses vision-guided robots and a host of other technologies. This water filter assembly machine uses vision-guided robots and a host of other technologies. The machine assembles water filters used in refrigerators. It sub-assembles the carbon block with a glue dam, inserts the carbon subassembly into the filter, caps it, spin welds the top on, and leak and flow tests each filter before putting a foil seal on it.

PRODUCT AUTOMATION EQUIPMENT AND SOLUTIONS THAT USE Robotic equipment, vision systems, conveyors, AND control systems.

While there are commonalities between the available tools every company has access to create your custom product automation machinery, such as robotic equipment, vision systems, conveyors, and control systems, Summit does not settle for the basics. No, when it comes to the design and building of your product automation systems, Summit takes things to the next level. What makes us different is the way we use and optimize the tools. We’re known for our agile project management processes that emphasize risk analysis, which results in customer machines producing high OEE (overall equipment effectiveness) metrics. This allows for Summit product automation machines and systems to improve our customers’ supply chains with:

✓ Higher quality products

✓ Lower manufacturing costs

✓ Faster speed to market

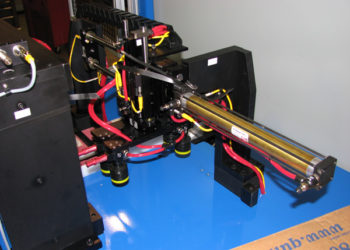

Drill Bit Packaging Equipment

This automated equipment was designed to place drill bits into envelopes and seal them. The machine packed drill bits from 1/8″–1/2″ from a single count up to 12-bits per package, while handling 14 envelope sizes that are made for a mix of low to high volumes.

Check out more product automation projects from Summit Engineered Automation.

A CUSTOM TOOLBOX OF PRODUCT AUTOMATION SOLUTIONS

It would be easy to approach our work with the same, limited toolbox of solutions that most others do, but that is not what sets us apart and makes us different. No, our solutions run much deeper. Whether you need control systems, custom product automation, specially designed robotics, or high-capability vision systems, Summit has you covered.

We don’t just offer cookie-cutter solutions. We offer custom product automation that thinks outside of the box. Our industry-recognized agile project management process, backed by a team of highly skilled and experienced industry veterans, allows us to do things you’ve only dreamed of until now with a sound understanding of automation risk management. That’s what makes our work so beautiful!

When we design your custom product automation system, we do so after gaining a clear understanding of your business and your specific needs. We then customize each part of our solution to not only meet your needs but exceed your expectations. This allows you to reduce costs, increase quality, and better manager results.

Industry-leading 4-hour service call response time

There is so much more that goes into great product automation than simply designing a functioning system. Our partnership with you goes beyond just developing and installing your product automation solution. At Summit Engineered Automation, we create long-lasting equipment and even longer-lasting relationships. That doesn’t mean there may never come a time when service work is required. When that time eventually comes, rest assured that our industry-leading 4-hour response time will have you back in operation quickly.

Tell us about your project.