Industrial Design Prototyping

Process-oriented risk assessment that perfects your final product

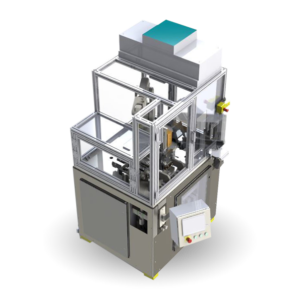

Industrial Prototyping

Prototyping is an essential step in successful product development, particularly when companies are investing in complex manufacturing solutions. With so much time, money, and effort pouring into the development process, the hands-on feedback gleaned from industrial prototyping is an invaluable tool for designers, engineers, UX developers, and end-users to ensure optimal functionality.

Whether you’re looking at the initial prototype for an individual part or the final prototype for a finished product, preliminary fault detection is the best way to guarantee the future health of your solution or system. That’s why Summit Engineered Automation includes multiple prototypes as part of our Agile Process.

Prototyping Processes

The prototyping process has come a long way—just like your options for automated solutions. As a result, we offer three unique prototyping methods catered to the size, timeline, and complexity of your project:

1. Rapid Prototyping

The availability and efficacy of rapid prototyping have increased exponentially in recent years as CAD software and 3D printing technology have advanced. With rapid prototyping, models can be produced overnight through computer-to-printer data transfer. As the name suggests, this speeds up the editing process and enables the creation of new prototype iterations with a single-day turnaround.

2. Iterative Prototyping

Iterative prototyping is a multi-step feedback loop that teams often use to address challenging design issues. This prototyping process involves manufacturing a prototype from an original design, testing it for form and function, tweaking and revising the design based on feedback, and then creating a new prototype for further testing. In many ways, rapid prototyping is simply a faster form of iterative prototyping.

3. Parallel Prototyping

Parallel prototyping is ideal for projects that need a bit of fine-tuning on the way to a blueprint. With parallel prototyping, teams create multiple versions of a design concept concurrently, then decide which elements are most successful. In comparing and optimizing several designs, teams can arrive at the ideal version before creating a physical prototype.

Types of Prototypes

No matter which method of industrial design prototyping you use, there are typically three types of prototypes you’ll encounter throughout the process:

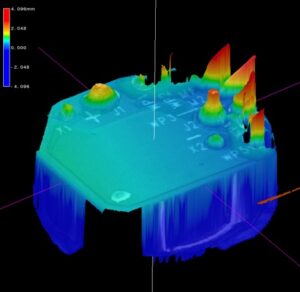

1. Form Prototypes

Form prototypes embody the outward aesthetic of your design to solicit user feedback, but don’t necessarily communicate function. Form prototypes are used for color, material, and design editing.

2. Function Prototypes

Function prototypes may not look at all like your finished product, but they demonstrate specific functions and test how those functions are working.

3. Pre-Production and Presentational Models

These models combine form and function into a single unit for presentations and pre-production.

Benefits of Industrial Design Prototyping

While engineering a custom solution gives you unprecedented control over the design, function, and aesthetic of your new product, it can be difficult to envision without a blueprint.

Industrial prototyping lets you see your future solutions in action. Moreover, it clarifies exactly what elements of form and function need to be tweaked before settling on the final product. With a hands-on model, you can fine-tune user experience, usability, and efficiency throughout the development process, ensuring a functional and sophisticated end result.

Plus, with a physical prototype in hand, stakeholders and executives can experience their transformative investment viscerally, providing confidence and reassurance throughout the development process.

The Summit Industrial Prototyping Process

The Summit process works to analyze and eliminate risk factors throughout process development and design. By offering a quick turnaround on prototypes for both parts and full systems, we ensure that your company receives the ideal solution for your unique needs.

Contact Summit to start refining your unique industrial design prototyping project today.