Using Automation to Improve Production

By automating part of or the complete process of manufacturing with the use of robotics, the quality and precision of the end product as well as the efficiency and safety of the process are improved. Lets dive into the positive impact that robotics have made on manufacturing and how they are helping to change industry standards.

Increased Product Quality

A consistent quality standard is an imperative measure of most manufacturers’ success. Robotics can ensure high quality, precise and consistent output with their many sensors and programming. Without the factor of human error, robotics can add accuracy with minimal errors and variations to your manufacturing process.

Lower Production Cost

Although robotics for manufacturing requires an initial investment, the long term savings on labor costs and errors are significant and make the investment worthwhile. Robots can work long hours in any environment with minimal maintenance. They will improve your profitability by greatly reducing long term production costs.

Increased Safety

Certain manufacturing processes take place in harsh environments and involve dangerous chemicals, tools or processes. By replacing these laborers with robotics, you will increase the safety of your workplace and keep human laborers safe from harm. Robotics can also be programmed to assist human laborers with safety features that reduce the risk of workplace injuries due to heavy lifting, sharp objects and more.

Partner with an Experienced Automation Expert

Summit Engineered Automation has worked tirelessly to improve the quality, efficiency, profitability and safety of our customers manufacturing processes. The Summit Agile Process ensures that your automation project is developed to provide a cost effective solution to your manufacturing pain points that with longevity you can rely on. Send your project in for a complimentary quote today. We would love to help you improve and simplify your manufacturing process!

Case Studies & Project Highlights

Pneumatics to Robotics – 5 million parts per year to 26 million!

Read a case study about how Summit helped a customer go from pneumatics to robotics to meet skyrocketing demands.

Included in the case study are pictures through the build out stage and videos about the different capabilities of the automation system! (Download PDF here)

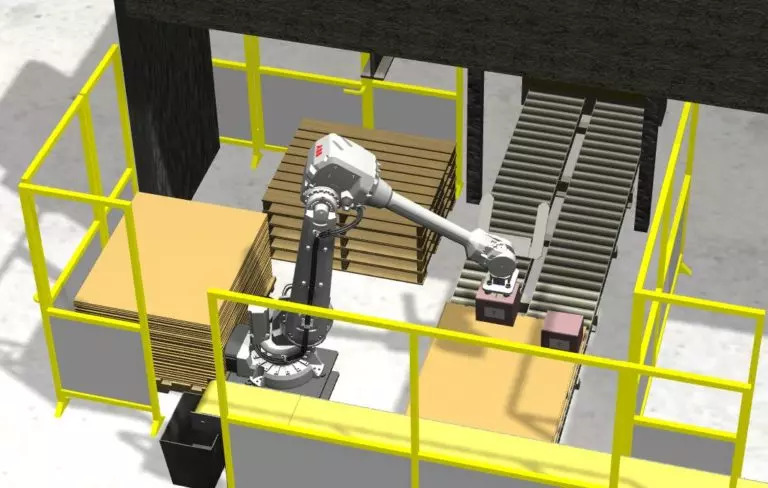

Watch a Video of a Robot Palletizing Salt Blocks

Looking to reduce human injury, Summit worked with a customer to create a robot that palletized 50lb salt blocks or mineral blocks. Read more or watch a video about the system.

View more pictures of projects and completed machines. Connect with us to discuss your manufacturing challenges today!